The adaptability of a centrifuges nuclear can be attributed to the many configurations and applications for which it is suited. From microcentrifuges that are used in genetic testing to heavy-duty machines for industrial processing, each is optimized for a particular purpose. The latest versions usually come with wireless monitoring systems, whose real-time data tracking occurs through mobile interfaces. Improved rotor materials allow for higher strength and corrosion resistance. In addition, automated calibration systems reduce maintenance time while improving consistency in performance. With these advancements, the centrifuges nuclear is a vital instrument in the continued search for scientific precision and efficiency.

The use of centrifuges nuclear traverses a number of scientific disciplines. In the manufacture of pharmaceuticals, it cleanses chemical compounds and removes residual unwanted matter. Biochemists employ centrifuges nuclear in fractionating cells and isolating organelles for subsequent studies. Drink producers utilize it to filter fluids and stabilize their products. The oil and gas industries utilize centrifuges nuclear to enhance fuel refining and clean products. {Keywords} can also be utilized in environmental analysis, aiding in the detection of pollutants in water and air samples. They are highly accurate and flexible, thus being a fundamental tool within laboratories and the manufacturing industry.

Future development of centrifuges nuclear will focus on precision control and data integration. Next-generation models will have sophisticated sensors that log every parameter of operation, generating total digital records for traceability. Performance trends will be predicted using machine learning, providing repeatable results. Hybrid centrifuges nuclear systems that can perform solid-liquid-gas separations will become a reality. Better safety designs and noiseless operation will make them easier to use. As research demands grow, these intelligent, automated centrifuges nuclear will be at the center of labs, enabling faster discovery and industrial productivity globally.

Routine maintenance of centrifuges nuclear begins with frequent cleaning and careful handling. Before each run, users should confirm that there are properly sealed, loaded tubes to prevent imbalance. The rotor, buckets, and seals should be washed gently and dried with air after each session. Periodic calibration checks ensure precise speed and temperature measurement. Rotor overloading is to be prevented since it will reduce motor life. With monitoring each maintenance cycle and adhering to safety protocols, laboratories can extend the functional life of centrifuges nuclear while ensuring precise performance.

Used in many applications, a centrifuges nuclear uses rotational motion to facilitate material separation. Working through centrifugal force, it accelerates sedimentation, allowing scientists to sort particles based on density. Used extensively in laboratories, production plants, and environmental testing, the centrifuges nuclear simplifies processes that would otherwise be tedious. Flexible, it can be used in anything from clinical diagnostics to food and drinks. With continuing improvement in rotor design and balance technology, centrifuges nuclear today offer improved stability, endurance, and accuracy of data than before.

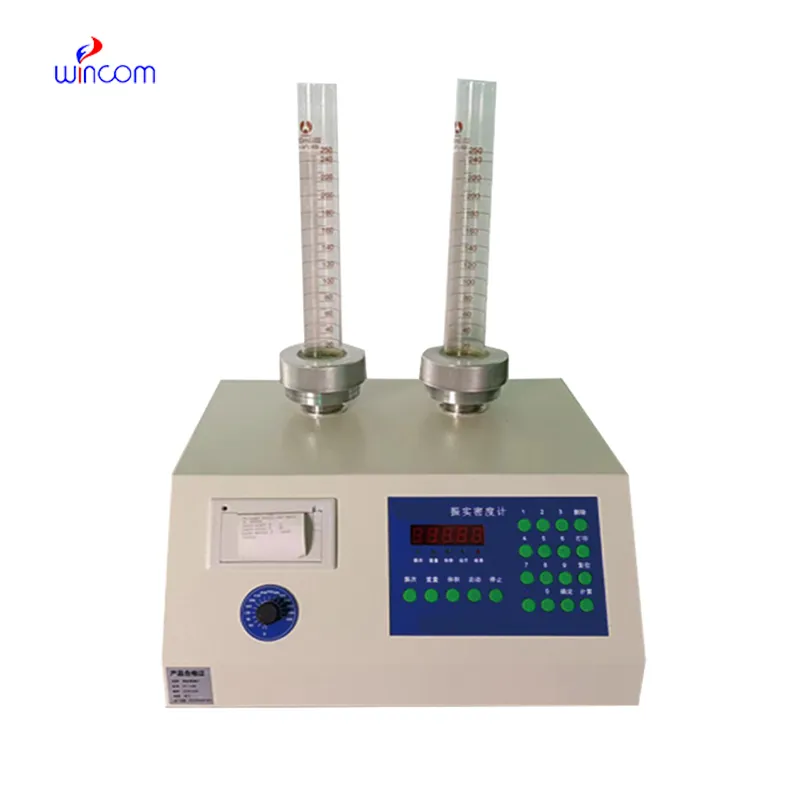

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We are planning to upgrade our imaging department and would like more information on your mri machin...

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China