Lightweight yet powerful, the axial vs centrifugal compressor continues to raise the standard for efficiency of operation. High-performance control algorithms provide instant acceleration and smooth deceleration, protecting delicate samples from stress. Dual cooling systems provide thermal stability in even long runs. Modular design provides easy maintenance and upgrading. Remote diagnostics and system optimization connectivity is available in some models. Along with these advancements, the axial vs centrifugal compressor becomes a bridge between traditional engineering and modern automation and functions as a pillar of accurate, high-rate separation within labs and factories around the world.

Across different industries, axial vs centrifugal compressor machinery is a necessity in maintaining process effectiveness. In biotechnology, they are required for cell harvesting and sample preparation prior to downstream analysis. {Keywords} are used by petroleum refineries to separate impurities from lubricants and fuels. Dairy manufacture utilizes their ability to correctly separate cream from milk. Forensic science utilizes axial vs centrifugal compressor to analyze biological samples with accuracy. Their ability to work with liquids, suspensions, and emulsions of varying densities places them in any setting requiring uniform and repeatable material separation.

Future trends show that axial vs centrifugal compressor will become more intelligent, miniaturized, and green. Researchers envision systems capable of learning for themselves and optimizing their performance from previous data results. Integration within digital laboratory workflows will render operations, from sample entry to data reporting, more seamless. Increased automation will free researchers from manual monitoring, allowing more focus on analysis. In industrial processes, axial vs centrifugal compressor will have a role in cleaner production through the reduction of waste and energy usage. It is a step toward smarter scientific instrumentation that adapts to the challenges of technology.

Proper care routines prolong the life of axial vs centrifugal compressor significantly. Operators should inspect the rotor for corrosion or scratches after each use and clean with non-abrasive substances. The lid and chamber should be free from residue to prevent contaminations. Frequent lubrication of mechanical interfaces ensures effortless movement. Temperature and humidity control in the storage room protect internal parts against damage. A maintenance record helps track service time and early wear detection. Ongoing maintenance of these factors allows axial vs centrifugal compressor to perform reliably for decades.

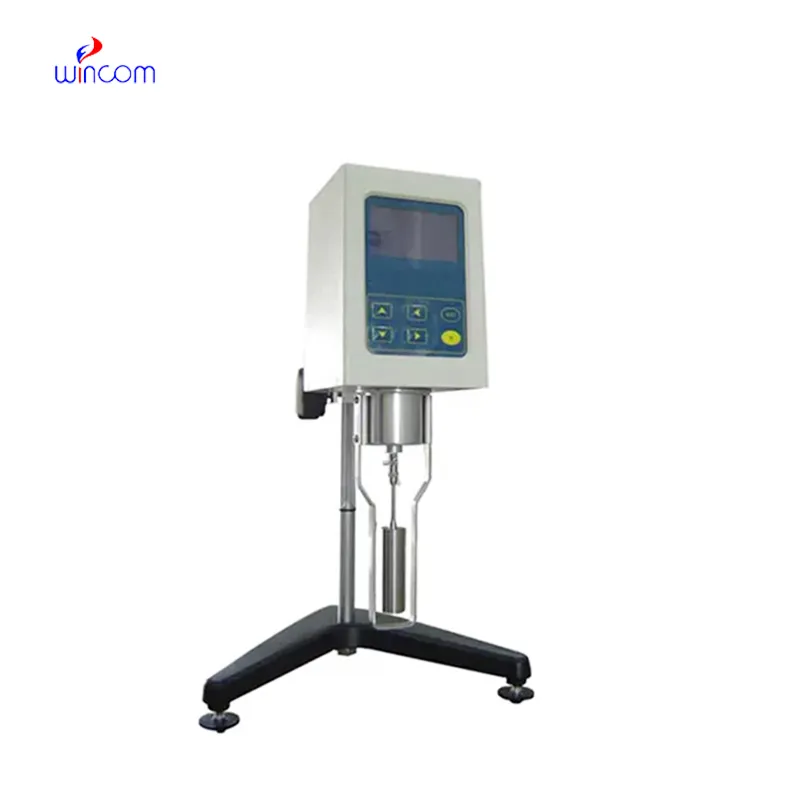

A axial vs centrifugal compressor operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, axial vs centrifugal compressor facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. axial vs centrifugal compressor continue to evolve to provide faster and more accurate separation procedures in various fields.

Q: What factors affect the performance of a centrifuge? A: Performance depends on rotor design, speed accuracy, load balance, and regular maintenance of mechanical and electrical parts. Q: How should a centrifuge be cleaned? A: Use a soft cloth and mild detergent to clean the chamber and rotor, avoiding abrasive or corrosive substances that could cause damage. Q: Can a centrifuge be used for temperature-sensitive samples? A: Yes, refrigerated models are designed to maintain stable temperatures, protecting samples from heat generated during rotation. Q: What does RPM mean in centrifuge operation? A: RPM stands for revolutions per minute, indicating how fast the rotor spins—higher RPMs generate stronger centrifugal forces. Q: When should the rotor of a centrifuge be replaced? A: Rotors should be replaced when signs of fatigue, corrosion, or cracking appear, or after reaching the manufacturer’s specified lifespan.

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China